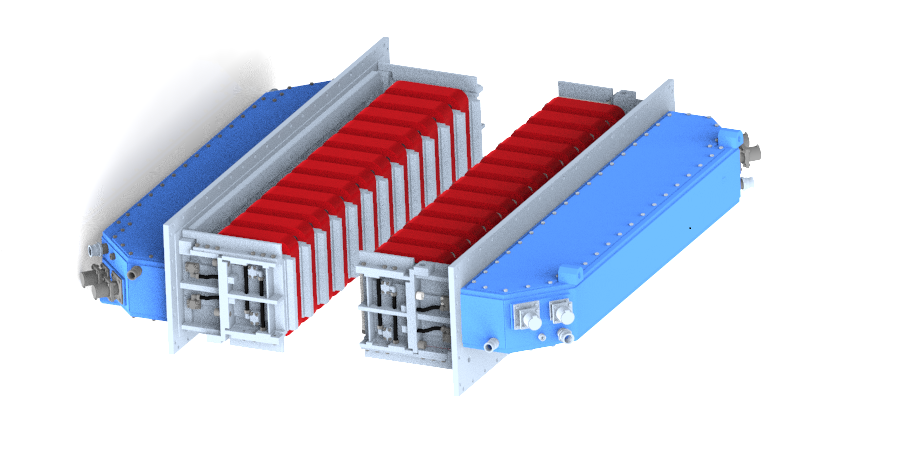

Slab M-EMS

Slab In-roll EMS is driven by two-phase or three-phase current generated by the frequency converter, linear induction motor with alternating magnetic field.The alternating magnetic field causes the molten steel to generate an induced current, which turns the molten steel into a current-carrying conductor, and moves under the action of the alternating magnetic field, that is, stirring the molten steel. The In-roll EMS replaces the continuous casting rolls in the segment of the slab CCM, and is in direct contact with the casting slab, with high stirring efficiency. In-roll EMS can effectively improve the casting quality of silicon steel, stainless steel, automobile sheet, deep-punching steel, flange steel and other steel grades, such as increasing the equiaxed crystal ratio of the casting slab, and improving the center segregation and porosity of the casting slab.

湘公網安備43060402000026號 湘ICP備16013601號-1

湘公網安備43060402000026號 湘ICP備16013601號-1